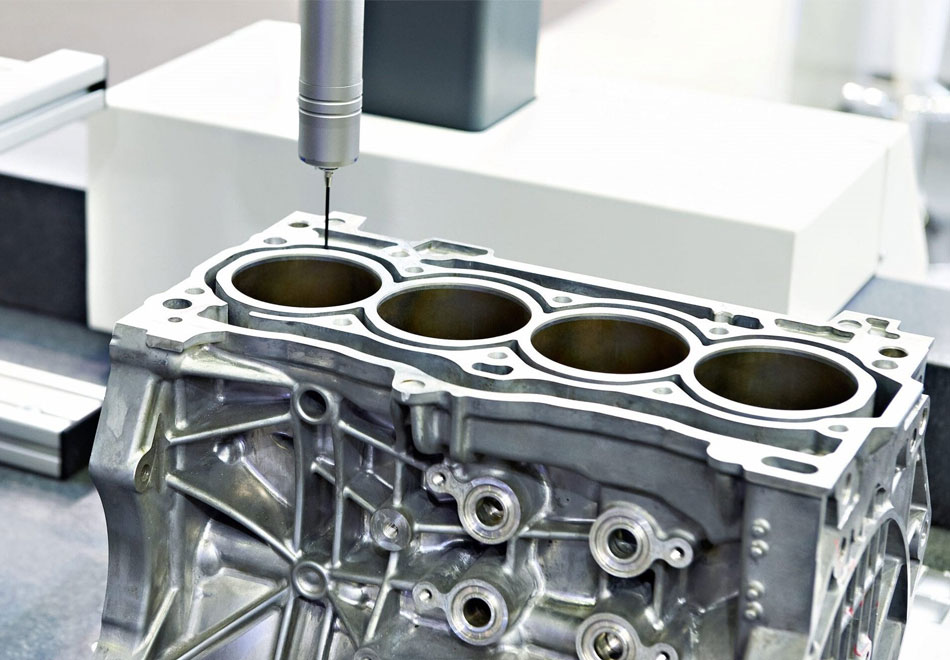

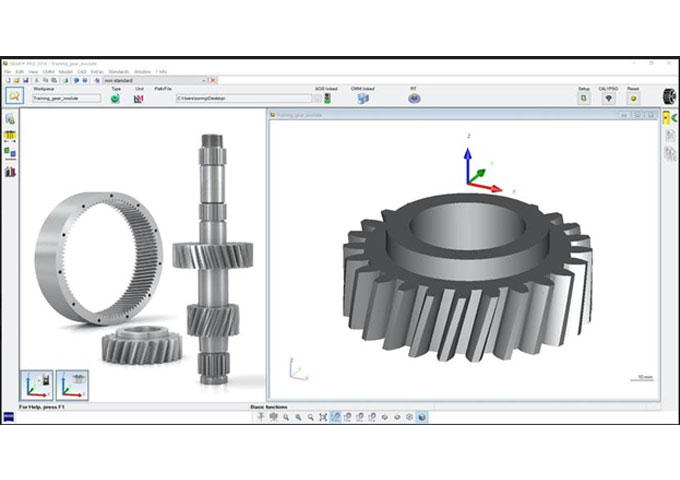

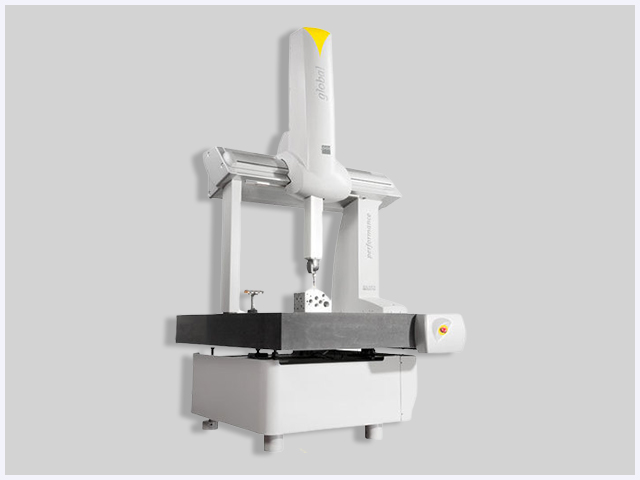

PRISMO from ZEISS is synonymous around the world for high-speed scanning and maximum accuracy. With length measurement error of leass than 1.2 um, ZEISS PRISMO is ideal when maximum demands on precision have to be met. The machine is supported with a rotory table for blades and gear measurements and rotationally symetric parts effectively.