Have a finished product but not its design?

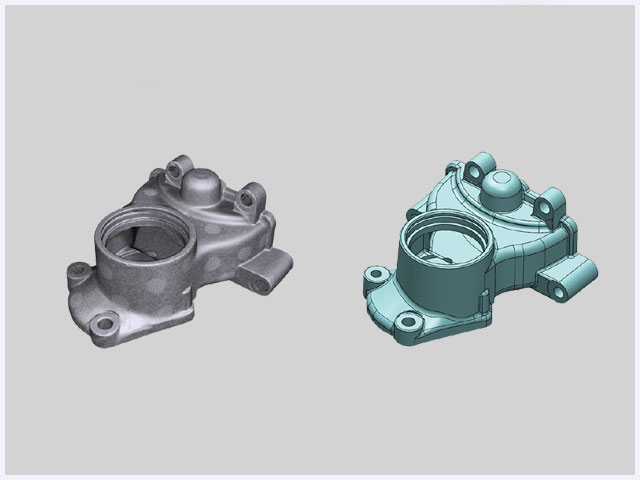

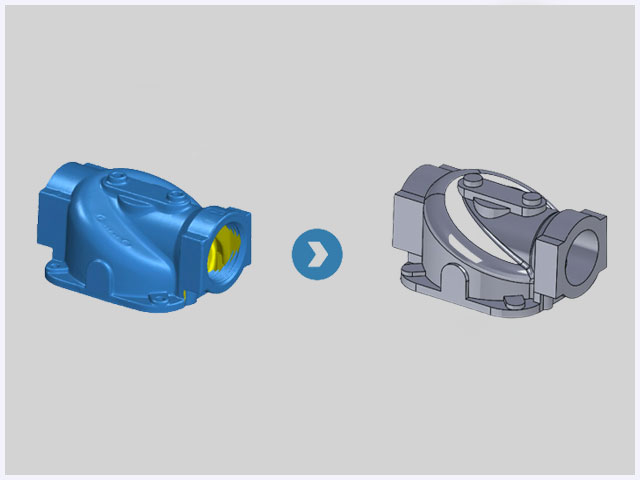

Reverse engineering is the solution which helps to get both stl data as well as Cad model which can then be used of inspection.

Reverse engineering is used to summarize the process of reconstructing an existing object known as backward engineering is a method through the application of which one attempts to understand through deductive reasoning how a device, accomplishes a task with very little insight into exactly how it was made.

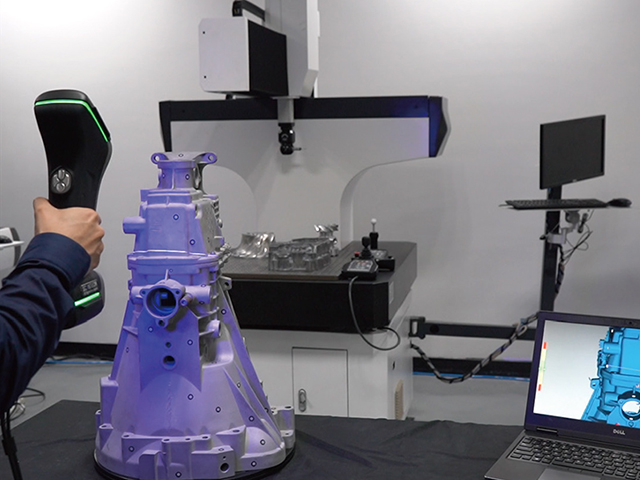

Reverse engineering is essentially studying a sample of a product, device or machine, to discover how it functions or was made. Quality Laboratory is specialized in reverse engineering using the portable laser scanner which can extract the digital data from the product which needs to be reverse engineered and then build the digital model which is close to the original product. We also have a precision CARL ZEISS PRISMO CMM with rotary table and noncontact measuring VMS system to support the scanner to arrive at the right revere engineering solution

Quality laboratory is also equipped to do 3-D inspection of components against CAD models and provide you with a consolidated report. Reverse engineering of gears both spur and helical profiles are carried out by the laboratory.

Please get in touch with the laboratory for any Reverse engineering solutions both prismatic and freeform profiles.